KKK-A-1822 E

permanently color coded or marked the entire length of the wire for identification with easily

read numbers and/or letters and routed in conduit or high temperature looms with a rating of

149° C (300° F). When cables are supplied by a component manufacturer to interconnect

system components, these cables need not be continuously color coded/identified. They shall

be coded/identified at the termination or interconnection points. All added wiring shall be located

in accessible, enclosed, protected locations and kept at least 15 cm (6 in.) away from exhaust

system components. Electrical wiring and components shall not terminate in the oxygen storage

compartment except for the oxygen controlled solenoid, compartment light, and switch plunger

or trigger device. Wiring necessarily passing through an oxygen compartment shall be protected

from damage (see 3.11.3). All conduits, looms, and wiring shall be secured to the body or frame

with insulated metal cable straps in order to prevent sagging and movement which results in

chafing, pinching, snagging, or any other damage. All apertures on the vehicle shall be properly

grommeted for passing wiring and conform to SAE 1292. All items used for protecting or

securing the wiring shall be appropriate for the specific application and be standard automotive,

aircraft, marine, or electronic hardware. Cable ties shall not be used to support harnesses, but

may be used for bundling purposes.

Electrical panels that are accessible to accidental contact shall have a protective cover, shield,

etc. to prevent shorts that can result in injury, fire, or damage to the electrical system.

3.7.2.1 WIRING CRITERIA.

All wiring (including grounds), devices, switches, outlets, etc., except circuit breakers,

shall be rated to carry at least 125 percent of the maximum ampere load for which the

circuit is protected.

A service loop of wire or harness shall be provided at all electrical components, terminals, and

connection points that permits at least two replacements of the wire(s) termination. All splices

and terminals provided shall comply with SAE J163, J561, or J928 as applicable. All wiring

between the cab/chassis and module in Type I and III ambulances shall be connected to a

terminal strip(s), block(s), or multi-pin

connector(s) near the point of entry to

the patient module. All terminals shall be

permanently numbered or coded.

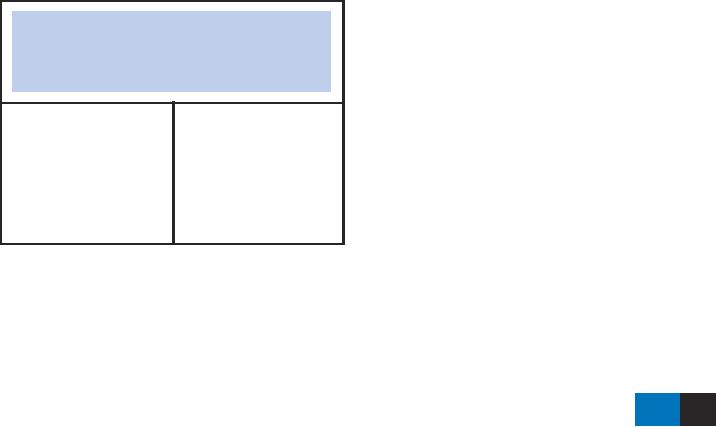

Circuit Breaker Rating (AMPS) /

Terminal strip(s), block(s), or multi-pin

Minimum Wire Size (AWG)

connector(s) shall be readily accessible

for checking and service. All exterior

10 A - 16 GA

50 A - 6 GA

wiring to lights or any other component

shall utilize sealed connectors or splices.

15 A - 14 GA

75 A - 4 GA

20 A - 12 GA

100 A - 2 GA

The ambulance electrical system shall

30 A - 10 GA

125 A - 0 GA

incorporate a master circuit breaker panel

with circuit breakers or other electronic,

40 A - 8 GA

150 A - 00 GA

non-disposable, current protection

devices, in each circuit, which comply with

SAE J553 Type I, or Type III (if circuit breaker is readily accessible for resetting by the driver or

EMT). When multiconductor cables/ribbon cables are used for low current (self limiting) circuits,

additional fuses/circuit breakers are not required. Additionally, one 15 ampere circuit breaker

shall be provided for future use. For high current circuits, where SAE Type I breakers are not

25

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business